Acrylic tray wani nau'in tire ne da ake amfani da shi a kowane fanni na rayuwa.Bayyanar sa na musamman, karko, da gyare-gyare ya sa ya shahara a kasuwa.Buƙatar kasuwar keɓance tiren acrylic yana haɓaka.Daban-daban masana'antu da aikace-aikace suna da nasu bukatun don girma, siffar, aiki, da ingancin trays.Madaidaitan tire na gargajiya ba zai iya cika waɗannan buƙatun ba, don haka gyare-gyaren trays ɗin acrylic yana ƙara zama mahimmanci.Ta hanyar gyare-gyaren trays na acrylic, kamfanoni na iya samun mafita na tire wanda ya dace da samfuran su, hanyoyin aiki, da hoton alama, inganta ingantaccen dabaru, rage hasara, da nuna hoto mai ƙwararru.

Taken wannan labarin shine tsarin gyaran tire na acrylic.Za mu gabatar da matakai daban-daban da kuma hanyoyin haɗin gwiwar gyare-gyare na acrylic tray daki-daki, ciki har da bincike da kuma sadarwa na buƙata, matakin ƙira, zaɓin kayan aiki da sarrafawa, samarwa da taro, da dai sauransu Ta hanyar zurfafa kallon waɗannan matakai, masu karatu za su koyi yadda za a tsara su. high quality-acrylic trays to mutum bukatun.

Na gaba, za mu bincika tsarin gyare-gyaren acrylic tray a cikin zurfin don taimakawa masu karatu su fahimta da amfani da ilimi a cikin wannan filin ƙwararru.

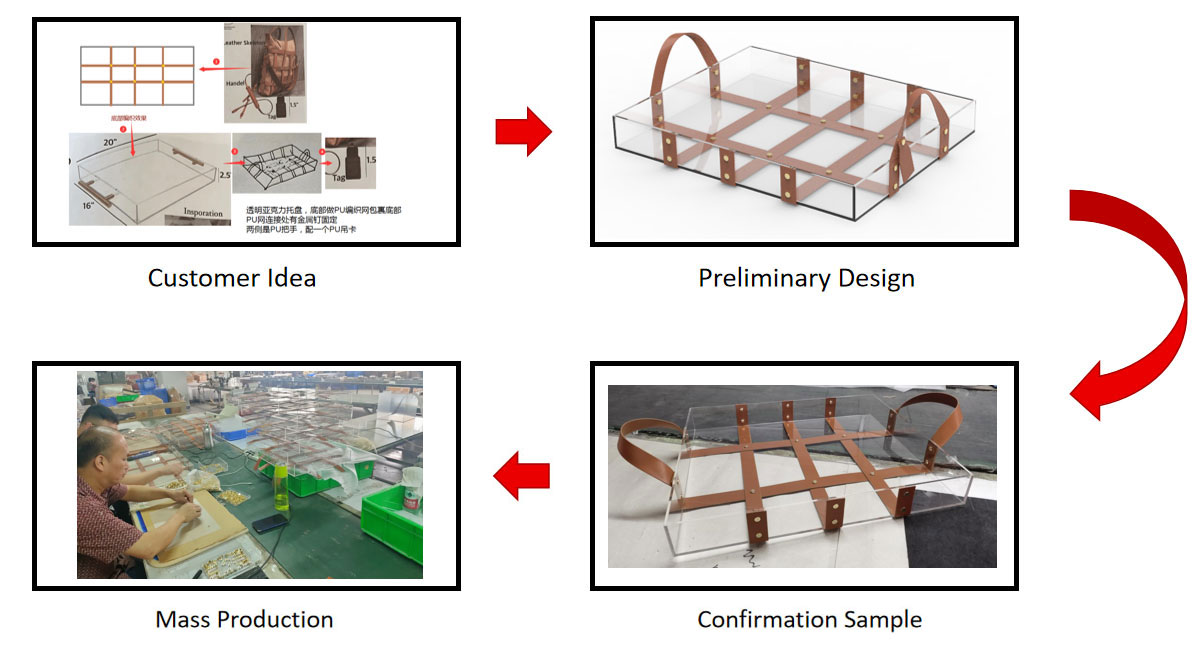

Acrylic Tray Custom Tsari

A) Binciken Bukatu da Sadarwa

A cikin aiwatar da gyare-gyaren tire na acrylic, nazarin buƙatu, da sadarwa matakai ne masu mahimmanci.Ya ƙunshi ingantaccen sadarwa da fahimta tsakanin abokan ciniki da masana'antun acrylic tray don tabbatar da cikakkiyar fahimta da ingantaccen fahimtar bukatun abokin ciniki.

Tsarin sadarwa tsakanin abokin ciniki da masana'anta:

Shawarar farko

Abokan ciniki sun fara tuntuɓar masana'anta don bayyana buƙatun su da niyyar gyare-gyaren tire na acrylic.Ana iya yin hakan ta waya, imel, ko taron fuska-da-fuska.

Tattaunawar Bukatu

Mai sana'anta yana gudanar da cikakken tattaunawar da ake buƙata tare da abokin ciniki don fahimtar takamaiman buƙatun abokin ciniki, gami da buƙatun dangane da girman, siffar, aiki, yawa, lokacin bayarwa, da sauransu.

Nasihar Fasaha

Masu sana'a suna ba da shawarwarin fasaha na sana'a bisa ga bukatun abokan ciniki, ciki har da zaɓi na kayan acrylic, yiwuwar zane, da sauran abubuwan da aka tsara.

Magana da Kwangila

Mai sana'anta yana ba da cikakken zance dangane da bukatun abokin ciniki da sakamakon tattaunawa kuma ya cimma yarjejeniya tare da abokin ciniki.

A cikin buƙatun bincike da matakin sadarwa, masana'antun acrylic suna buƙatar rayayye sauraron buƙatun abokan ciniki, gabatar da shawarwarin ƙwararru, da kula da sadarwar lokaci da amsawa.Cikakken fahimta da ingantaccen fahimtar bukatun abokin ciniki zai kafa tushe mai ƙarfi don ƙirar ƙira da matakan samarwa na gaba, tabbatar da cewa tire na acrylic na ƙarshe na iya cika tsammanin abokin ciniki da buƙatun.

Idan kuna kasuwanci, kuna iya so

B) Tsarin Zane

Tsarin ƙira shine maɓalli mai mahimmanci a cikin tsarin gyare-gyaren acrylic tray, wanda ya haɗa da tsara takamaiman ƙirar ƙirar acrylic tray bisa ga bukatun abokin ciniki da buƙatun fasaha.Wadannan sune mahimman matakai da matakai a cikin tsarin ƙira:

1. Zane na Farko:

- Dangane da buƙatu da ƙayyadaddun ƙayyadaddun fasaha da abokin ciniki ya bayar, mai yin tire yana aiwatar da ƙirar farko.Wannan ya haɗa da tantance girman, siffa, kamanni, da sauran abubuwan asali na tiren acrylic, da zana zane-zane na farko.

- Yi la'akari da yanayin amfani da buƙatun tire, kamar ƙarfin ɗaukar nauyi, yanayin tarawa, yanayin sarrafawa, da dai sauransu, don tabbatar da aiwatarwa da aiwatar da ƙira.

2. 3D Modeling da Kallon gani:

- Yin amfani da software na ƙira da ke taimaka wa kwamfuta, ana aiwatar da ƙirar 3D, kuma ƙirar farko ta canza zuwa takamaiman ƙirar 3D.Don haka zan iya nuna mafi kyawun bayyanar da tsarin tire, kuma in taimaka wa abokan ciniki don fahimtar bayyanar ƙarshen samfurin.

- Masu ƙera za su iya amfani da ƙirar 3D don gabatarwa na gani don abokan ciniki su sake duba ƙira kuma su ba da shawarar gyare-gyare.Wannan yana taimakawa tabbatar da cewa ƙirar ta dace da tsammanin da buƙatun abokin ciniki.

3. Yi La'akari da Girman, Siffa, da Aiki:

- A cikin tsarin ƙira, mai ƙira yana buƙatar yin la'akari da girman, siffar, da aikin tire.Girman ya kamata ya dace da bukatun abokin ciniki da buƙatun aikace-aikacen aikace-aikace, siffar ya kamata ya dace da samfurin kuma mai sauƙin sarrafawa da tari, kuma aikin ya kamata ya dace da manufar amfani da buƙatun musamman na tire.

- Hakanan ya kamata a yi la'akari da cikakkun bayanai kamar sarrafa gefuna, tsarin ɗaukar kaya, da ƙirƙira ƙira na tire don tabbatar da kwanciyar hankali, dawwama, da amincin tire.

4. Bita kuma Tabbatarwa akai-akai:

- Dangane da ra'ayoyin abokin ciniki da ra'ayoyin, masana'antun suna yin canje-canjen da suka dace da gyare-gyare, har sai tsarin ƙira na ƙarshe don samun ƙwarewar abokin ciniki da gamsuwa.

- Wannan na iya buƙatar sadarwa da gyare-gyare da yawa don tabbatar da cewa ƙira ta yi daidai da tsammanin abokin ciniki kuma ana la'akari da yuwuwar da abubuwan farashi na ainihin masana'anta.

Ba za a iya watsi da mahimmancin lokacin ƙirar acrylic tire ba.Ta hanyar yin la'akari da girma, siffar, da aiki tare, masana'antun suna iya zana tiren acrylic na musamman wanda ya dace da bukatun abokin ciniki.Titunan da aka ƙera a hankali na iya haɓaka ingantaccen kayan aiki, rage asara, da haɓaka hoton alamar.Sabili da haka, ya zama dole a kula da cikakkun bayanai a cikin tsarin ƙira don tabbatar da ma'ana da yuwuwar tsarin ƙirar don cimma sakamako mafi kyau na gyare-gyare.

C) Zaɓin Kayan aiki da Gudanarwa

Zaɓin kayan abu da sarrafawa shine muhimmin ɓangare na tsarin gyare-gyaren acrylic tray, wanda ya haɗa da zaɓi na kayan acrylic masu dacewa da aiki da samarwa da suka dace.Ga bayanin da ya dace:

1. Halaye da Zaɓin La'akari na Kayan Acrylic:

- Fassara: Acrylic yana da kyakkyawar fahimi, yana mai da shi kyakkyawan abu don nunawa da nuna samfuran.

- Durability: Acrylic yana da babban juriya ga tasiri da lalacewa, kuma yana iya jure matsi mai girma da amfani a cikin kayan aiki da wuraren ajiya.

- Nauyin haske: Idan aka kwatanta da gilashi, kayan acrylic yana da haske da sauƙi don sarrafawa da aiki.

-

Customizable: Acrylic za a iya sassauƙa sarrafa da kuma musamman don saduwa da bukatun daban-daban siffofi da kuma girma dabam ta hanyar matakai irin su thermoforming, yankan, hakowa, da sauransu.

- Mai hana ƙura da tsayayyen abu: Tireshin acrylic na iya samun hurumin ƙura da sifofi don kare samfur daga ƙura da wutar lantarki.

Lokacin zabar kayan acrylic, ya kamata a yi la'akari da waɗannan abubuwan:

- Yanayin amfani da buƙatun tire, gami da zafin jiki, zafi, hulɗar sinadarai, da sauransu.

- Ƙarfin ɗaukar nauyi da buƙatun dorewa na tire.

- Kasafin kudi na abokin ciniki da takura.

2. Acrylic Tray Processing Tsari da Fasaha:

- Yanke da gyare-gyare: Dangane da zane-zane na zane, an yanke takardar acrylic zuwa siffar da ake so da girman da ake so ta amfani da na'ura mai yankan ko fasahar yankan Laser.

- Thermoforming: Ta dumama da siffata, yanke acrylic takardar an kafa a cikin takamaiman siffar tire.Ana iya yin hakan da bindiga mai zafi, farantin zafi, ko kayan aikin injin ƙira.

- Gudanar da ramuka da ramummuka: Yin amfani da injin hakowa ko fasahar yankan Laser, ana sarrafa ramukan da ramummuka akan farantin acrylic don sauƙaƙe tari, gyarawa, ko wasu takamaiman dalilai.

-

Jiyya na saman: Dangane da buƙatun, tiren acrylic yana goge, yashi, ko sauran jiyya na saman don haɓaka ingancin bayyanar da taɓawa.

Tsarin sarrafawa yana buƙatar ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun masana don tabbatar da ingancin sarrafawa da daidaiton tiren acrylic.A lokaci guda, ya kamata a kula da matakan tsaro yayin aiki don tabbatar da amincin masu aiki da aikin yau da kullun na kayan aiki.

Tare da zaɓin kayan da ya dace da ingantattun dabarun sarrafawa, masana'antun na iya samar da ingantattun trays na acrylic na musamman waɗanda ke biyan bukatun abokin ciniki.Tare da kyakkyawan aiki da amintacce, waɗannan trays ɗin suna ba da ingantacciyar mafita don kayan aiki da hanyoyin adana kayayyaki.

Barka da zuwa ga al'ada acrylic trays factory!Muna ba da sabis na gyare-gyaren masana'antu, don haka ko kuna buƙatar keɓance abubuwanku na sirri ko kuna son ƙirƙirar samfuri na musamman don taron kamfani, zamu iya biyan bukatunku.Daga ƙira zuwa samarwa, ƙwararrun ƙungiyarmu za su yi ƙoƙari don ƙirƙirar trays ɗin acrylic na musamman don ku, ta yadda zaku iya jin ƙwarewa ta musamman a kowane amfani.

D) Ƙirƙira da Taro

Tsarin samarwa da bayanan fasaha na trays acrylic shine mabuɗin don tabbatar da ingancin samfurin ƙarshe.Ga bayanin da ya dace:

1. Tsarin samarwa da cikakkun bayanai na fasaha:

- Shirya kayan: Shirya zanen gadon acrylic da ake buƙata da sauran abubuwan da aka haɗa bisa ga girman da buƙatun sifa da ƙira ta ƙayyade.

- Yanke da gyare-gyare: Yin amfani da na'ura ko fasahar yankan Laser, an yanke takardar acrylic bisa ga bukatun ƙira, kuma ana amfani da tsarin thermoforming don siffanta shi zuwa siffar tire.

- Machining ramuka da ramummuka: Yin amfani da injin hakowa ko fasahar yankan Laser, ana sarrafa ramukan da ramummuka a cikin takardar acrylic don tara tire, gyarawa, ko wasu takamaiman dalilai.

- Jiyya na saman: gogewa, yashi ko sauran jiyya na farantin acrylic don haɓaka ingancin bayyanar da taɓawa.

- Majalisar: Dangane da buƙatun ƙira, an haɗa farantin acrylic da sauran abubuwan haɗin gwiwa, kamar kusurwoyi na haɗin gwiwa, gyare-gyaren sukurori, da sauransu, don tabbatar da daidaiton tsari da amincin aikin tire.

2. Kula da Inganci da Taro:

-

A cikin tsarin samarwa, kula da inganci yana da mahimmanci.Ya kamata masana'antun su kafa tsauraran matakan kula da ingancin inganci da gudanar da bincike da gwaje-gwaje don tabbatar da inganci da daidaiton kowane hanyar haɗin samarwa.

- A cikin yankan da kafa mataki, wajibi ne don tabbatar da cewa girman, siffar, da kusurwar takardar acrylic sun dace da bukatun ƙira don kauce wa ɓacin girman girman ko mummunan lalacewa.

- Lokacin sarrafa ramuka da ramummuka, bincika ko matsayinsu da girmansu daidai ne, kuma tabbatar da santsi da daidaiton ramuka da ramummuka.

-

A cikin matakin jiyya na saman, ana aiwatar da isassun goge baki da yashi don tabbatar da cewa saman tire ɗin ya yi santsi kuma ba shi da karce, kuma an cire duk wani ƙura ko datti.

-

A cikin tsarin haɗuwa, dacewa da kwanciyar hankali na kowane bangare ya kamata a duba a hankali don tabbatar da cewa tsarin tire yana da ƙarfi kuma yana aiki.

Ta hanyar kula da inganci mai mahimmanci da dubawar taro, masana'antun za su iya tabbatar da cewa babu matsala masu inganci ko lahani da ke faruwa yayin samar da trays na acrylic.Wannan yana taimakawa wajen samar da ingantattun samfuran tire masu inganci waɗanda ke biyan buƙatun abokin ciniki da tabbatar da aminci da dorewa a cikin kayan aiki da wuraren ajiya.

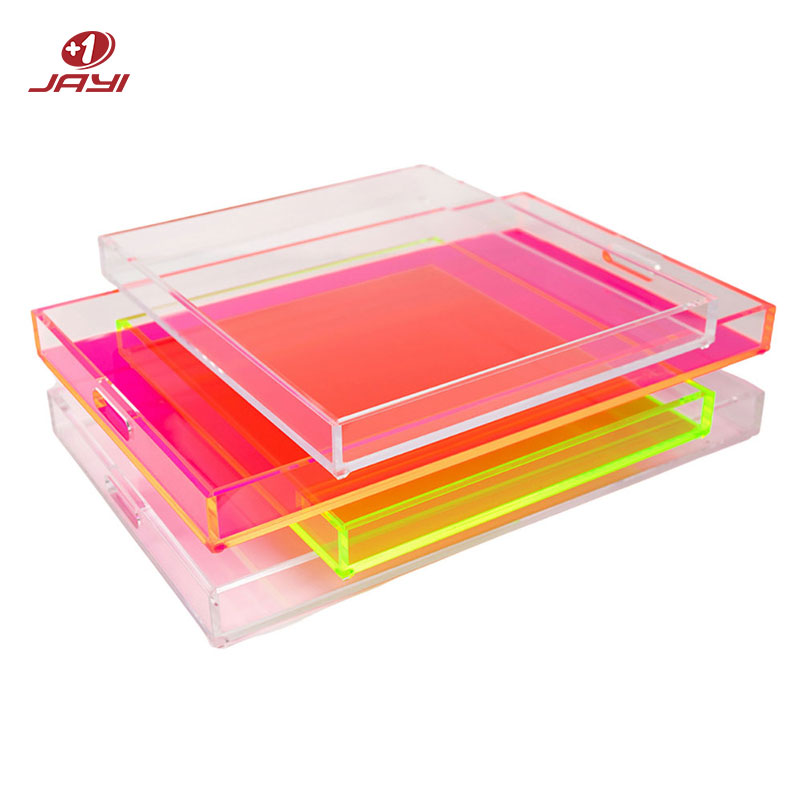

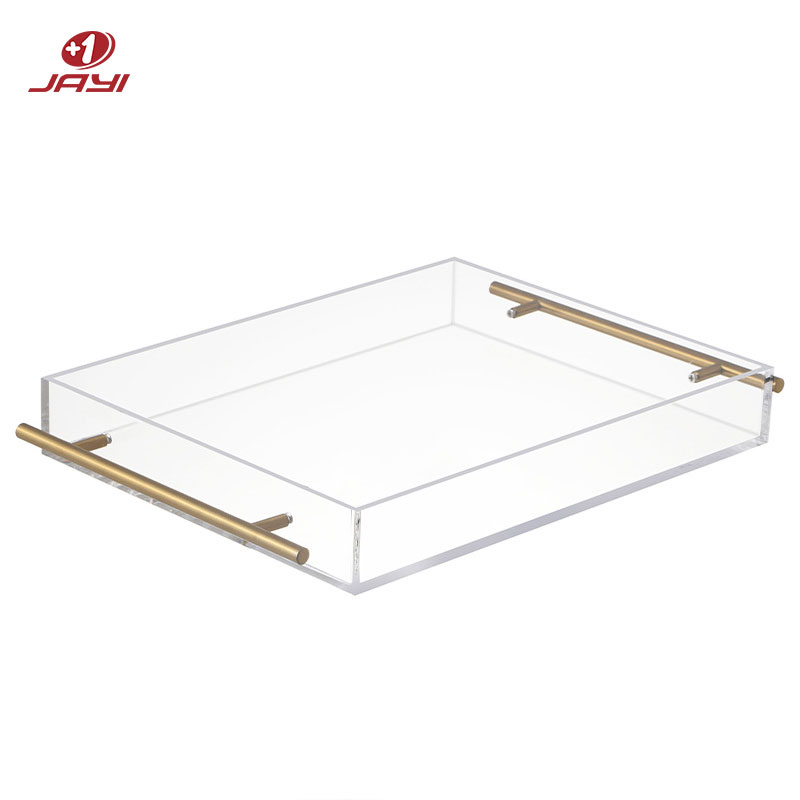

Custom Acrylic Tray Case

Takaitawa

Wannan takarda ta tattauna tsarin ƙira da haɗin kai na acrylic trays, yana mai da hankali kan mahimmancin kula da inganci da kuma nazarin taro yayin aikin ƙirƙira.Ta hanyar kula da ingancin inganci da dubawar taro, masana'antun za su iya tabbatar da cewa babu wani matsala mai inganci ko lahani da ke faruwa yayin samar da trays na acrylic, don haka samar da samfuran tire masu inganci da aminci.

Tsarin Gyaran Tire na Acrylic yana da fa'idodi masu zuwa:

- Keɓancewa: Ana iya keɓance trays ɗin acrylic bisa ga buƙatun abokin ciniki da buƙatun, gami da girman, siffa, aiki, da bayyanar.Wannan yana ba da damar acrylic trays don saduwa da takamaiman bukatun masana'antu da aikace-aikace daban-daban, samar da keɓaɓɓen mafita.

- Nauyi mai Sauƙi da Dorewa: Kayan acrylic yana da ƙarancin ƙima, yana sanya trays ɗin acrylic ɗan haske, kuma mai sauƙin ɗauka da aiki.A lokaci guda kuma, kayan acrylic shima yana da kyakkyawan karko kuma yana iya jure nauyi mai nauyi da juriya mai tasiri, yana tabbatar da yin amfani da tire na dogon lokaci a cikin kayan aiki da wuraren ajiya.

- Fassara da tasirin nuni: Tire na acrylic yana da fa'ida mai kyau, yana iya nuna samfuran a sarari, haɓaka tasirin nuni da kyawun samfuran.Wannan yana da mahimmanci musamman ga masu siyarwa da masana'antar nuni don jawo hankalin masu amfani yadda yakamata.

- Ayyukan hana-tsaye da ƙura: kayan acrylic za a iya bi da su tare da anti-static don guje wa lalacewar samfura da abubuwan lantarki waɗanda ke haifar da kutsewar lantarki.Bugu da ƙari, shimfidar wuri mai laushi na acrylic tray kuma yana rage yawan ƙura da datti, yana kula da tsabtar samfurin.

Acrylic Tray Customization Process yana da Faɗin Kasuwa Hasashen:

- Sana'a da masana'antar adana kayayyaki: Ana amfani da trays ɗin acrylic ko'ina a cikin masana'antar dabaru da masana'antar ajiya, wanda zai iya haɓaka haɓakar sufuri da sarrafa sarrafa kayayyaki.Tare da haɓakar buƙatun dabaru na duniya, buƙatun kasuwa na tiren acrylic zai ci gaba da ƙaruwa.

- Retail da nuni masana'antu: Acrylic trays iya samar da wani fili samfurin nuni sakamako, sa su yadu amfani a cikin kiri da nuni masana'antu.Tare da karuwar gasa ta tallace-tallace da kuma fifikon masu amfani ga bayyanar samfur, buƙatar kasuwa don tiren acrylic zai ci gaba da girma.

- Electronics da semiconductor masana'antu: Anti-static Properties na acrylic trays sanya su manufa zabi a cikin Electronics da semiconductor masana'antu.Tare da ci gaba da haɓaka samfuran lantarki da haɓaka buƙatu, trays acrylic a cikin tsammanin kasuwancin masana'antu suna da faɗi sosai.

Don taƙaitawa, tsarin gyaran tire na acrylic yana da fa'idodi da yawa kuma yana da fa'ida mai fa'ida a kasuwa a cikin kayan aiki, ɗakunan ajiya, dillali, nuni, kayan lantarki, da masana'antar semiconductor.Masu kera za su iya biyan buƙatun abokin ciniki ta hanyar hanyoyin samar da ƙwararru da sarrafa inganci, da kuma samar da ingantattun samfuran acrylic na keɓaɓɓen tire.

Lokacin aikawa: Agusta-29-2023